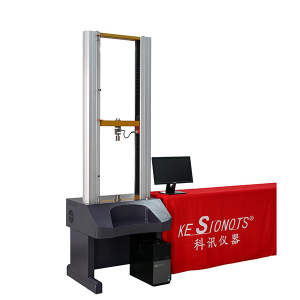

Tensile Testing Machine

Application

Tensile Testing Machine

Computer tensile testing machine is mainly used for metal wire, metal foil, plastic film, wire and cable, adhesive, man-made board, wire and cable, waterproof materials and other industries of tensile, compression, bending, shearing, tearing, stripping, cycling and other ways of mechanical properties test. Widely used in factories and mining enterprises, quality supervision, aerospace, machinery manufacturing, wire and cable, rubber and plastic, textile, construction materials, household appliances and other industries of material inspection and analysis.

The design of computer bending testing machine and auxiliary tools, with beautiful appearance, convenient operation, stable and reliable performance characteristics. The computer control system controls the servo motor rotation through the DC speed regulation system, and then slows down by the deceleration system, through the high-precision lead screw pair to drive the mobile beam up and down, to complete the tensile and other mechanical performance test of the sample, this series of products has no pollution, low noise, high efficiency, with a very wide speed regulation range and beam moving distance. With a wide variety of auxiliary tools, it has a very broad application prospect in the mechanical property test of metals and non-metals. The machine is suitable for quality supervision, teaching and scientific research, aerospace, iron and steel metallurgy, automobile, rubber and plastic, woven materials and other test fields.

Specification

Tensile Testing Machine

|

1, the maximum test force |

2000kg |

|

2. Accuracy level |

0.5 |

|

3. Load measurement range |

0.2%-100% FS; |

|

4. Allowable error limit of the test force indication value |

within ±1% of the indication value |

|

5, test force value resolution |

1/±300000 |

|

6, deformation measurement range |

0.2% -- 100%FS |

|

7. Error limit of deformation indication value |

within ±0.50% of indication value |

|

8. Deformation resolution |

1/60000 of the maximum deformation |

|

9. Displacement indication error limit |

within ±0.5% of the indication value |

|

10, displacement resolution |

0.05µm |

|

11, force control rate adjustment range |

0.01-10%FS/S |

|

12, rate control accuracy |

within ±1% of the set value |

|

13, deformation rate adjustment range |

0.02-5%FS /S |

|

14, deformation rate control accuracy |

within ±1% of the set value, |

|

15, displacement speed adjustment range |

0.5-500mm /min |

|

16, displacement rate control accuracy |

rate ≥0.1≤50mm/min, set value within ±0.1%; |

|

17, constant force, constant deformation, constant displacement control range |

0.5%--100%FS; |

|

18, constant force, constant deformation, constant displacement control accuracy |

set value ≥10%FS, set value within ±0.1%; For setpoint <10%FS, within ±1% of the setpoint |

|

19, effective travel |

600mm |

|

20, the main body size (length x width x height) |

800mm*500mm*1100mm |

|

21. Supporting fixtures |

customized according to customer products |